Challenge Intralogistic

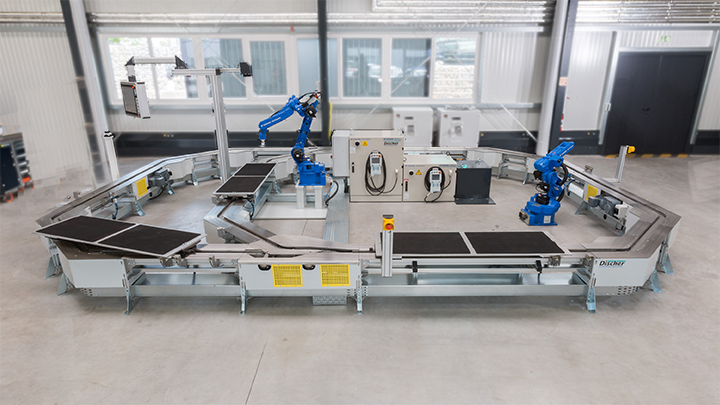

LogicTrack is designed as a continuous conveyor for the transport of workpieces. The goods to be transported can be transported from one or more admitting facility(ies) to one or more discharge point(s). Continuous conveyors usually work fully automatically, so there is no need for additional operating personnel. One feature of LogicTrack is to transport quite large quantities or units within a short time.

LogicTrack is designed for permanent takeover or delivery. It is loaded and unloaded during operation. Therefore, the friction conveyor chain does not have to be stopped during this process. The adjustable driving force, the buffer capacity or the automatic drive decoupling during carrier congestion are additional aspects that speak for the use of the LogicTrack System. With its simple, modular design and its relatively low energy costs in continuous operation, LogicTrack finds its use as an extremely efficient system in various areas of intralogistics.

LogicTrack from Discher Automatisierungstechnik sets new standards with regard to the handling of weight and dimensions of respective workpieces. Also, a further argument for LogicTrack is the consistent minimizing wear accompanied by a maximum of precision. In addition, this system will simultaneously create a building block towards Industry 4.0.

LogicTrack

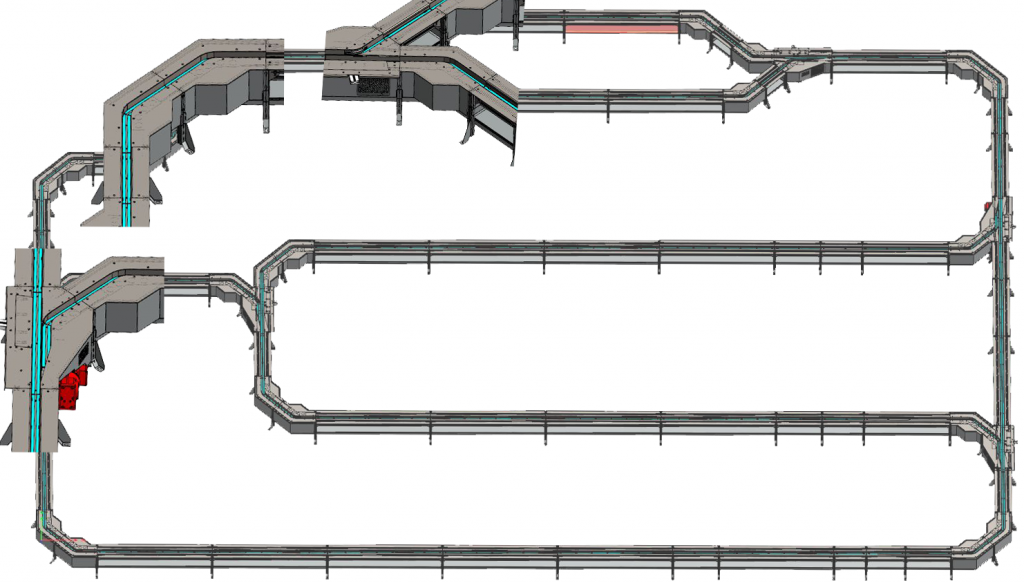

provides the needed support to be ahead of the pricing pressure increases, for example through global competition. Discher LogicTrack uses your resources comprehensively and optimally with intelligent material flow control. Whether in hall or machine chaining - LogicTrack networks your systems in such a way that the maximum capacity utilization of the respective individual systems/transport participants is always guaranteed. Standardisation shall also be seen as a further added value. Other features of the LogicTrack system include high availability with a correspondingly low failure rate and maximum flexibility.

LogicTrack is consistently modularly built. Thus, a flexible adaptation to your transport and production requirements is possible. Standard rail lengths of 2000 mm and the modular system consisting of various track switch, stoppers and curve elements make the structure correspondingly adaptable and simple. Inside the track, the special endless chain transports the respective workpiece carrier.

A safe and precise transport to the corresponding stations takes place based on the friction principle. Soft stops guarantee a maximum precision and a very low minimum of wear. Automatic stretching devices ensure a low maintenance. At the same time, a high working load up to 300 kg is provided.

Workpieces of special length? No problem!

By coupling of two workpiece carriers, the transport of particularly long workpieces is possible. With regard to occupational safety, it should also be emphasized that all switches are made crimp-proof. The speed of the workpiece carrier is also located below the safety-critical speed. Therefore, LogicTrack does not need additional personal protection in the form of an enclosure or the like.

LogicTrack modules ... to adapt to your requirements

☑️ Length of standard trunking 2000 mm

☑️ Several tracks combinable

☑️ Crush-free track switch

☑️ Soft-Stopper

☑️ Product scanner for material tracking

☑️ Interface for robot integration

☑️ Turning device

☑️ Material flow control via visualization

☑️ Connection to existing ERP systems

The LogicTrack software serves as a bridge towards Industry 4.0.

The elaborated combination clearly highlights the difference to comparable systems. LogicTrack is the intralogistic system with a future. With the LogicTrack software, the processes are controlled, and the produced goods are fed to the processing stations or the transport participants in a targeted manner - Just-In-Sequence. In this case, occupied workstations are recognized and driven around if needed. Blocked tracks are detected and reported. The processes are monitored accordingly, and there is also an interface for the connection to the superordinate production control system.

Your advantage

☑️ Modular construction

☑️ Low wear due to highly abrasion-proofed surfaces

☑️ High availability (> 90 %)

☑️ No additional anti-crush protection required

☑️ Intelligently controlled material flow

☑️ Masses from 300 g to 300 kg

☑️ Components | transported material up to a length of 5 m

☑️ Fast adaptation to new processes

☑️ High efficiency

Higher productivity through consistent realization of experience

Whether in the realization of tasks in the laser sector (car body production), in the automotive industry, in the pharmaceutical industry or in the field of furniture production, our experience has been consistently used in every application. Named car manufacturers increased their productivity by about 80% per production line. At the same time, the ergonomics were improved, and measures for optimal, preventive maintenance were exemplary integrated. Without LogicTrack, a team of seven operators had previously dealt with the loading and unloading of laser systems. Statistically speaking, by using LogicTrack, only 0.5 system operators are required in this regard. Ergonomically, the system represents a quantum leap. Without LogicTrack, parts with a weight of approx. 12.5 kg were inserted to the workholder manually and with immense physical effort. Now, this happens by using LogicTrack and by integrating handling robots. Here, a station time of about 15 seconds is reached.

Before the integration of LogicTrack one operated in this case (laser park) in the deficit range. With the use of the LogicTrack system, the tide turned. The laser systems are now operated in a very profitable, economical area.

"With LogicTrack, our company has developed an effective, modular system that connects the machines involved in the process intelligently and fills the gaps in the value-added chain."

Reinhard Discher

(Managing Director, Discher Automatisierungstechnik GmbH)