Your supplier for special machine construction, plant engineering and automation technology

Discher Automatisierungstechnik GmbH offers you sophisticated solutions in the field of special machine construction, which meet your needs. Use our experience and expertise to optimize your processes. We exclusively employ qualified specialists who work for you in the areas of design, production, programming, assembly, commissioning, and service.

Reduce your production costs and increase your productivity and quality with our automation solutions for the special machine construction. We offer you optimal and rational solutions in this regard.

Special machine construction - Where can it utilized for you?

☑️ We design and plan your machine and plant according to your budget specifications.

☑️ Everything from a single source - from consulting, planning, design of the mechanics and control system of your plant to production, programming, assembly, commissioning, and service and retrofitting.

☑️ Automation of work steps | Are you planning to have loaded your plant automatically?

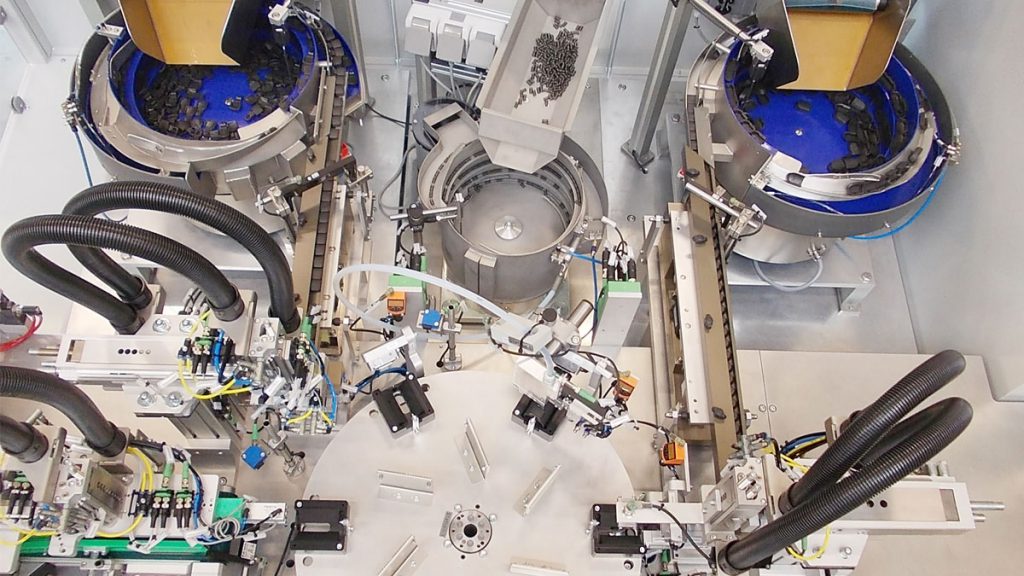

☑️ Fully automatic assembly of components/assemblies | Would you like to assemble a filigree component, which consists of several individual parts, fully automatically?

☑️ Quality control by safe and sophisticated visualization systems

☑️ Optimization the make-ready time of your plant | We can achieve to optimize the make-ready time of your plant by a close cooperation of our design and software department.

☑️ Optimization of station times | With our software solutions adapted to your needs, we achieve the optimum for your station times.

☑️ System integration in plant engineering | Would you like to optimize or extend your plant or to modify it for a new product variant?

Special machine construction - our range of services:

- Let us know your requirements, your performance, and quality specifications as well as your budget. Accordingly, we will design, develop and produce your special machine or plant to your specifications.

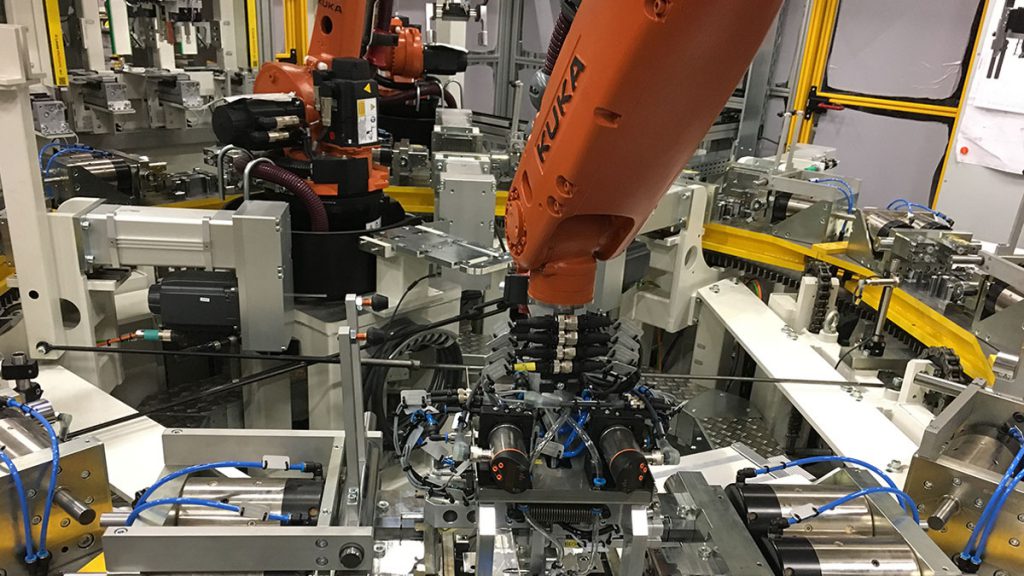

- Latest automation technology, from control and drive technology, robotics to sophisticated visualization

- Complex visualization technology in connection with handling and robot applications enables e.g. the automatic recognition, measurement, and evaluation as well as the sorting and positioning of your production components in the respective special system.

- Use of modern tools (such as E-Plan, Siemens TIA, etc.) in the control structure - for the control system of your special plant

- Development of your special purpose machine and plant and the associated assembly with modern 3D-CAD systems (CATIA /SolidWorks, etc.)

- Active quality and safety management with implementation of FMEA (Failure Mode and Effects Analysis) by our design engineers

- More than 25 years of manufacturing experience of special machines and production lines

- Quality certification DIN EN ISO 9001