Precision from Discher Automatisierungstechnik

Precision from Discher Automation Technology

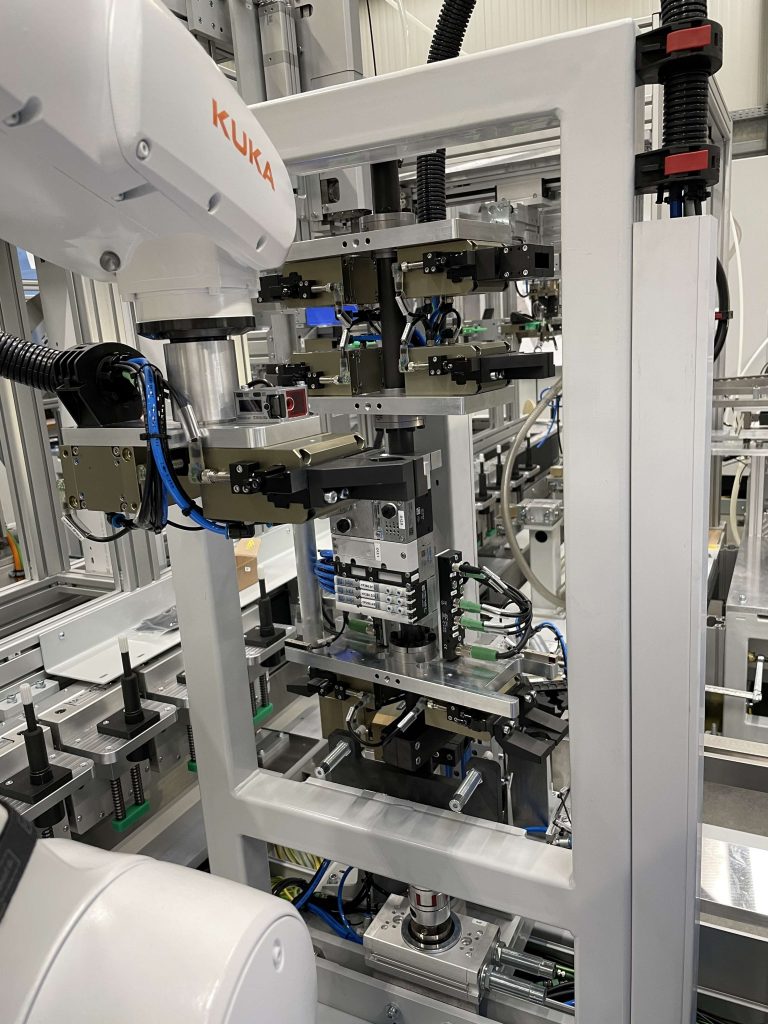

This is system technology that requires maximum precision with regard to the assembly task of the component to be produced and the subsequent quality inspection. The systems currently under construction use feed and conveyor systems from B&R's "SuperTrac" series. The majority of the required handling tasks are performed by KUKA robots. The complete assembly technology is developed, designed and manufactured at Discher Automatisierungstechnik. For the purpose of quality inspection, various camera systems are used in this regard, which are individually programmed for the respective inspection task. An extremely low error rate is the unconditional standard here. 28 years of experience and specialists of different fields under one roof speak for themselves. Convince yourself of our performance, according to the motto "Everything from one source".